The LHM-B Ceramic Media Ball Mill Classifying Production Line is the best solution and specifically design for high purity material, grinding liner and grinding media adopt corundum, cobblestone, quartz, zirconia according to the material request. Inwall of equipments used corundum, zirconia,rubber wear resistant material for protecting, classifier wheel adopts tungsten carbide and ceramic composite material, and this is no metallic contamination. It is widely used in high purity and ultrafine processing of quartz,feldspar,zircon sand,zirconium silicate,α-alumina,ceramic material,luminescent material,electronic material and fireproof material etc.

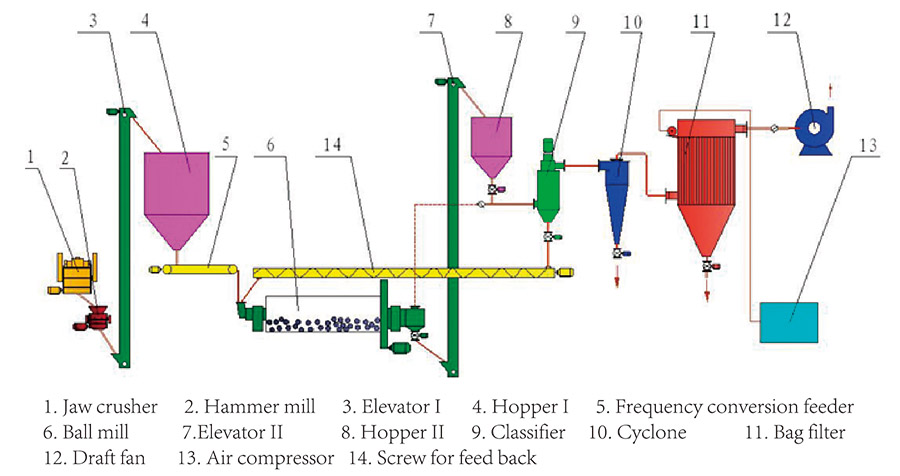

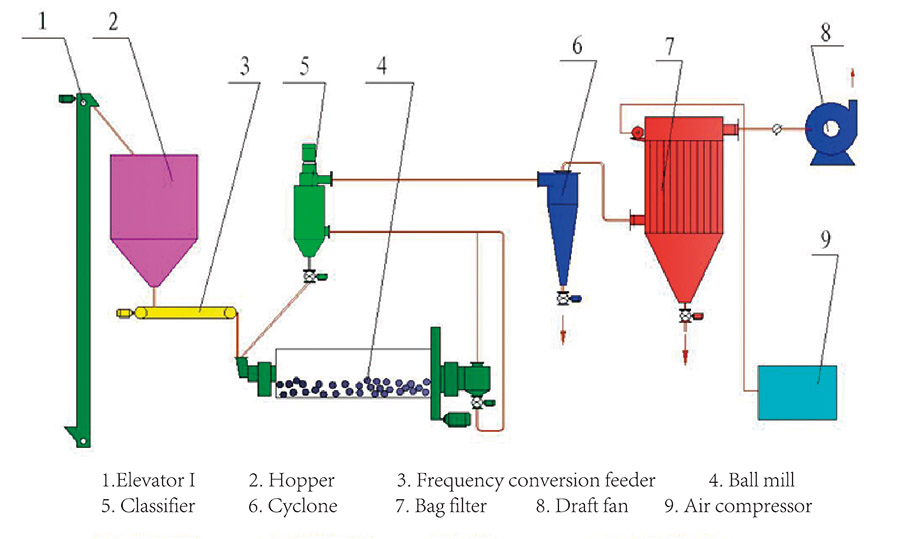

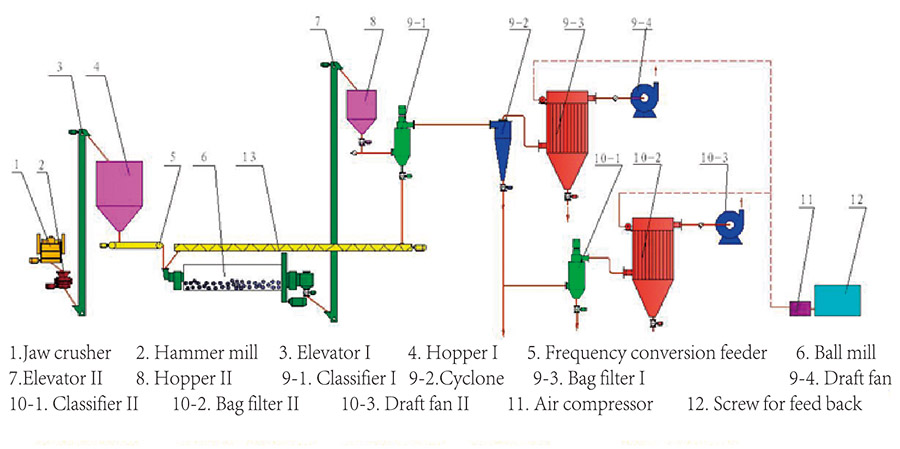

Application It is widely used in high purity and ultrafine processing of quartz, feldspar,zircon sand, zirconium silicate, α-alumina,ceramic material, luminescent material, electronic material and fireproof material etc.

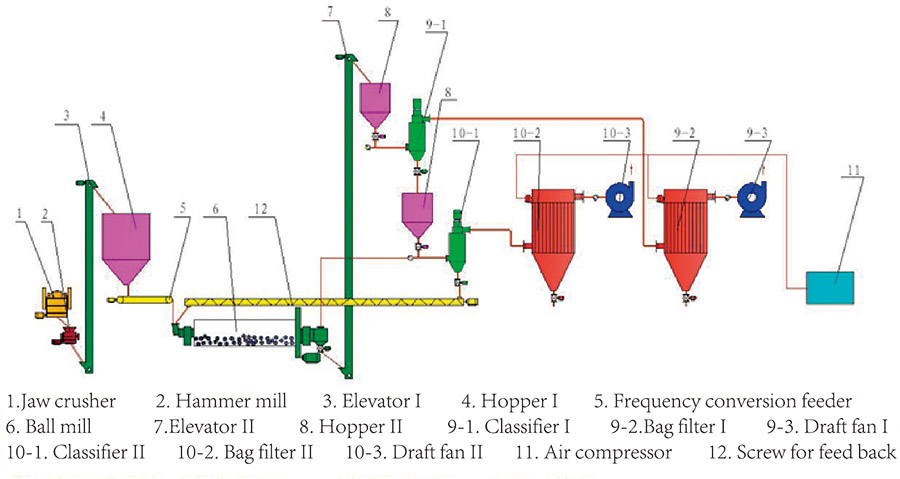

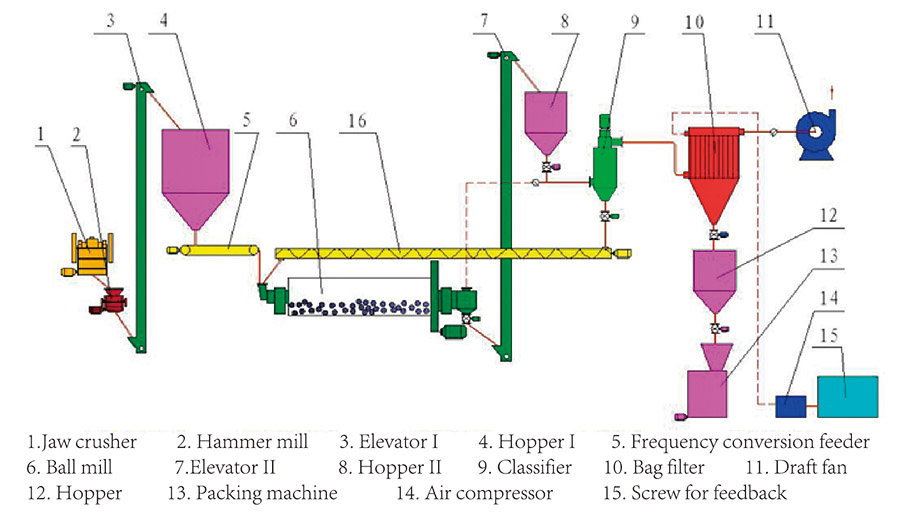

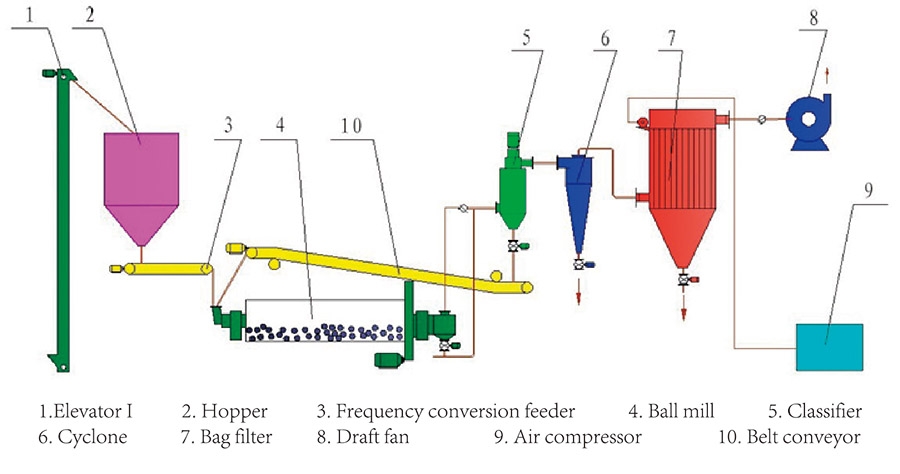

Application It is widely used in high purity and ultrafine processing of quartz, feldspar,zircon sand, zirconium silicate, α-alumina,ceramic material, luminescent material, electronic material and fireproof material etc.

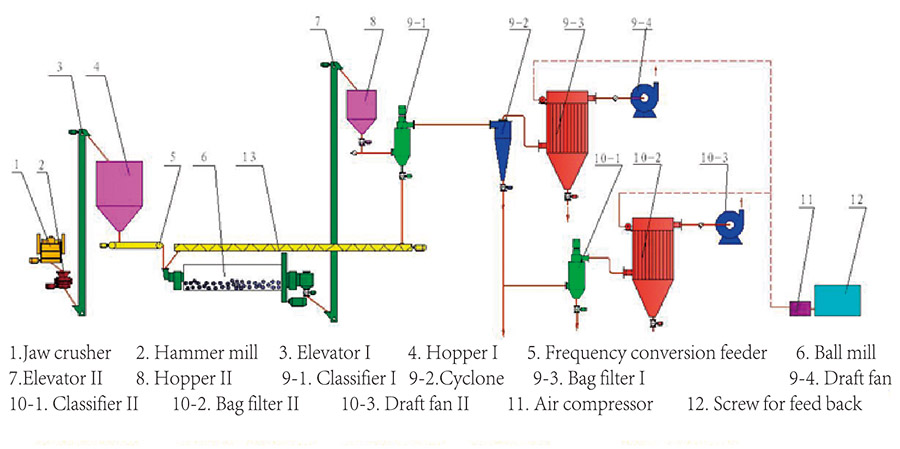

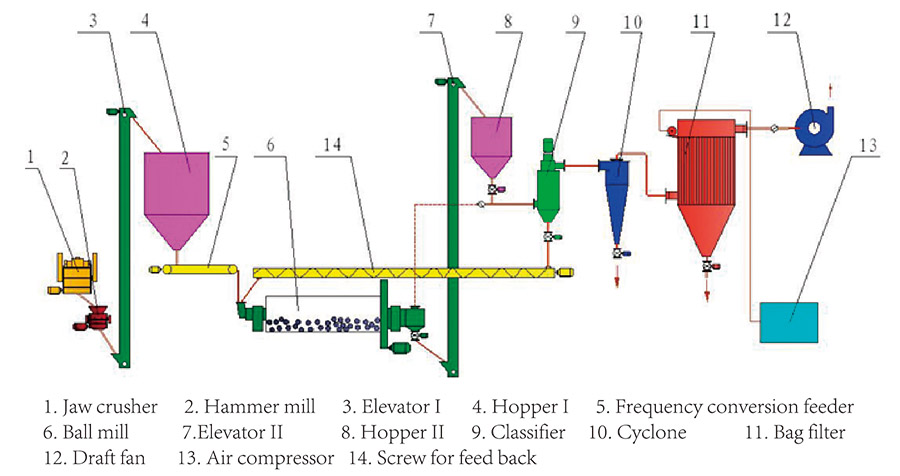

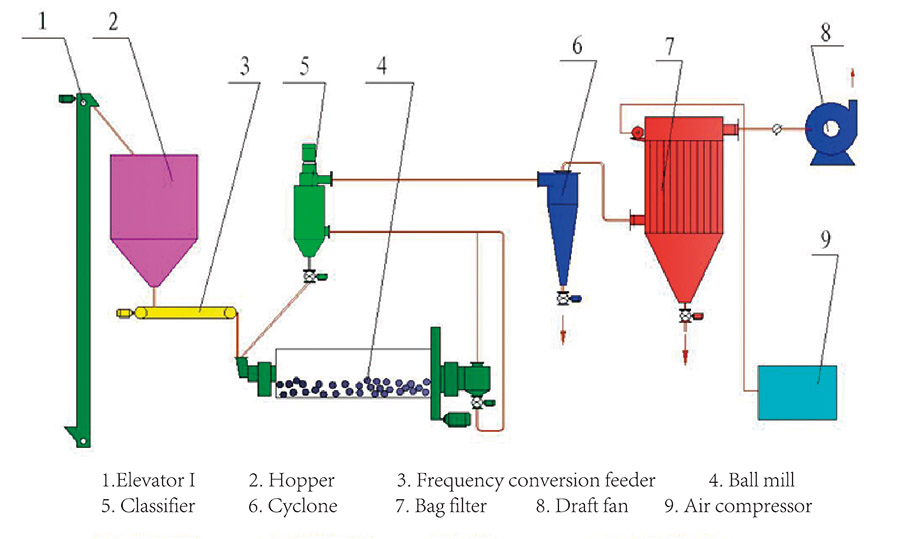

Application It is widely used in high purity and ultrafine processing of quartz, feldspar,zircon sand, zirconium silicate, α-alumina,ceramic material, luminescent material, electronic material and fireproof material etc.

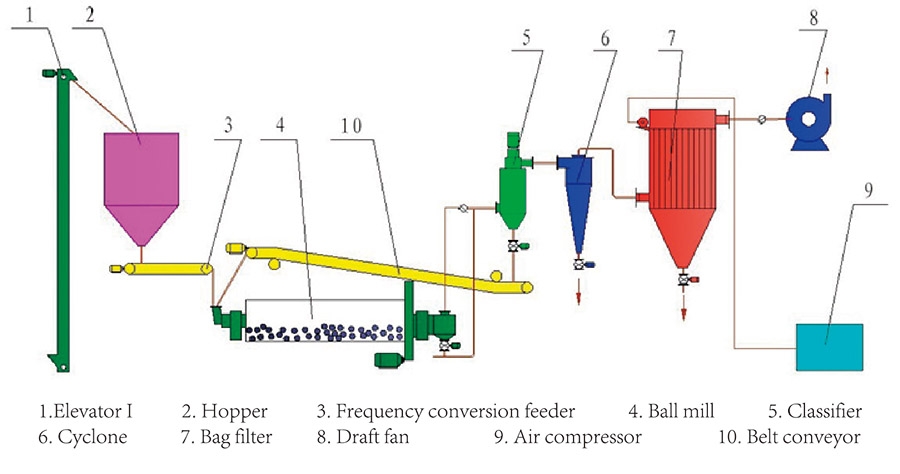

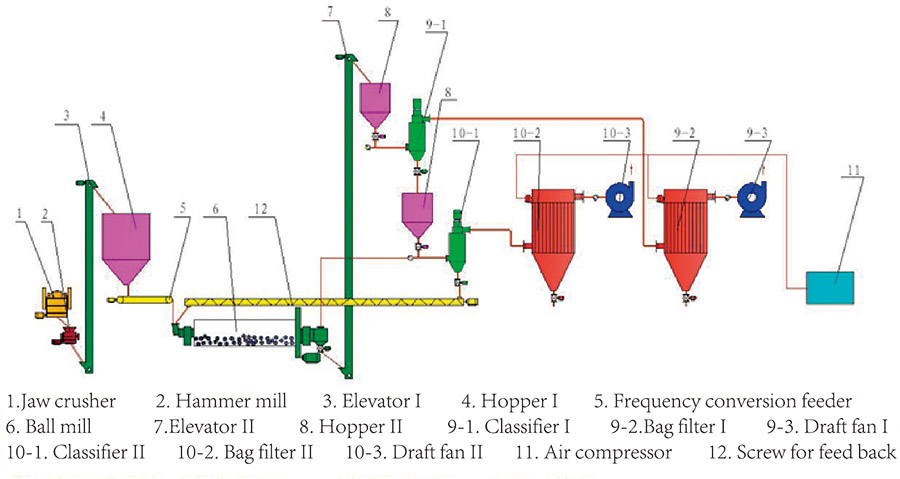

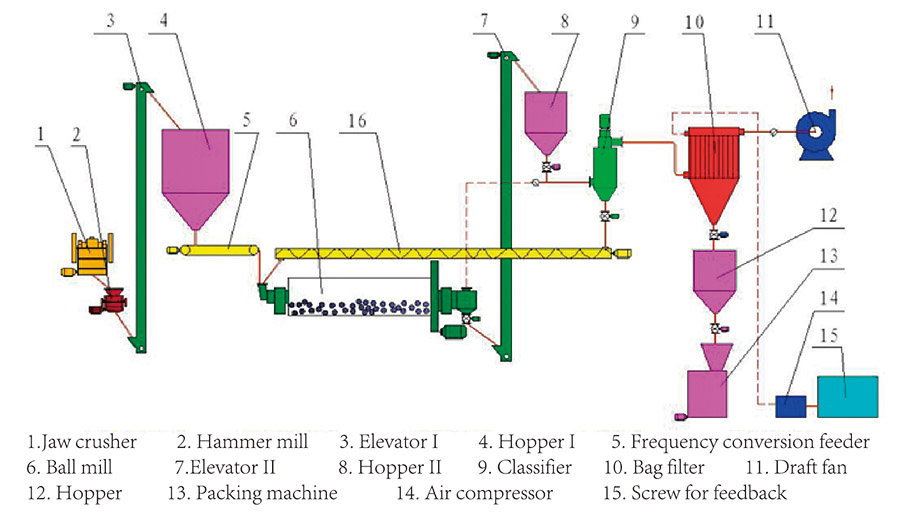

Application It is widely used in high purity and ultrafine processing of quartz, feldspar,zircon sand, zirconium silicate, α-alumina,ceramic material, luminescent material, electronic material and fireproof material etc.